What are the primary materials used in 3D printing in the UAE?

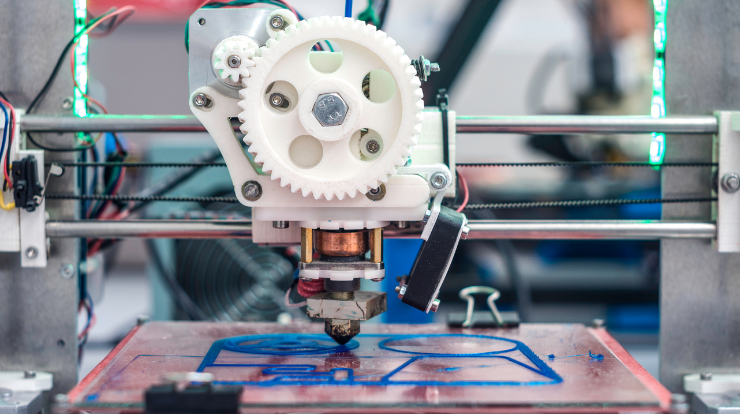

3D printing, also known as additive manufacturing, is a versatile technology that can work with a wide range of materials. The United Arab Emirates (UAE) has been at the forefront of adopting 3D printing technology, with applications spanning various industries. This section explores the primary materials used in 3D printing in the UAE, their characteristics, and their applications.

Thermoplastics (PLA, ABS, PETG, etc.):

Thermoplastics are among the most commonly used materials in 3D printing. Polylactic Acid (PLA) is a biodegradable and environmentally friendly thermoplastic derived from renewable resources such as corn starch or sugarcane. Acrylonitrile Butadiene Styrene (ABS) offers high-impact resistance and is commonly used in industrial applications. Polyethylene Terephthalate Glycol (PETG) combines the best properties of both PLA and ABS, offering durability, flexibility, and ease of printing. These materials are widely used in prototyping, consumer products, and various engineering applications in the UAE.

Polyamide (Nylon):

Polyamide, commonly known as Nylon, is a strong and flexible material used in 3D printing for applications that require high tensile strength and durability. It is suitable for functional prototypes, end-use parts, and components in industries such as aerospace, automotive, and healthcare.

Photopolymer Resins:

Photopolymer resins are used in Stereolithography (SLA) and Digital Light Processing (DLP) 3D printing UAE technologies. These resins are cured by UV light, resulting in high-resolution prints with smooth surface finishes. There are various types of photopolymer resins, including standard resins for general prototyping, tough resins for impact resistance, flexible resins for rubber-like properties, and biocompatible resins for medical applications.

Polypropylene (PP):

Polypropylene is a widely used thermoplastic known for its excellent chemical resistance and low density. In 3D printing, PP offers good fatigue resistance and is suitable for applications involving living hinges, containers, and lightweight parts.

Metals:

Metal 3D printing, also known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), involves using metal powders to create fully dense metal parts. Aluminum, stainless steel, titanium, and nickel-based alloys are commonly used metals in industrial-grade 3D printing applications in the UAE. Metal 3D printing finds applications in aerospace, automotive, healthcare, and engineering sectors where high strength and precision are essential.

Carbon Fiber Reinforced Polymers:

Carbon fiber-reinforced polymers combine the strength and stiffness of carbon fibers with the versatility of thermoplastics. This results in materials with excellent mechanical properties, high strength-to-weight ratio, and resistance to wear and abrasion. In the UAE, these materials are used in industries such as motorsports, aerospace, and robotics.

Wood and Metal Composites:

Wood and metal composites offer unique aesthetic qualities, blending the appearance of wood or metal with the convenience of 3D printing. These composites are suitable for artistic applications, architectural models, and decorative pieces.

Bioinks and Biodegradable Materials:

In the field of biomedical 3D printing, bio-inks and biodegradable materials are used to create tissues, implants, and medical devices. These materials have biocompatibility and can be tailored to specific medical requirements. Bioinks may consist of living cells, extracellular matrix materials, and other biocompatible compounds.

Silicone:

Silicone 3D printing is used to create flexible and soft structures suitable for applications such as prosthetics, wearable devices, and custom seals. Silicone materials offer excellent elasticity, durability, and resistance to extreme temperatures.

Ceramics:

Ceramic materials are utilized in 3D printing for applications that require high-temperature resistance, electrical insulation, and excellent mechanical properties. Ceramic 3D printing enables the production of complex ceramic structures, such as custom-made ceramic components, dental restorations, and ceramic molds for investment casting.

Concrete and Construction Materials:

In the construction industry, 3D printing is being increasingly used to create large-scale structures using concrete and other construction materials. This approach, known as 3D concrete printing, allows for faster and more efficient construction processes, reduced material waste, and the potential for complex architectural designs. The UAE has embraced 3D printing in construction as a means to accelerate infrastructure development and address housing needs.

Food Materials:

Food 3D printing is an emerging field that explores the creation of edible and customized food products. Ingredients such as chocolate, sugar paste, and dough can be used in 3D printers to produce intricate and decorative food items. Food printing has potential applications in confectionery, culinary arts, personalized nutrition, and specialized diets.

Hydrogels:

Hydrogels are water-based materials that have a high water content and exhibit gel-like properties. They are used in 3D bioprinting for tissue engineering and regenerative medicine applications. Hydrogel-based scaffolds can mimic the natural environment for cells to grow, facilitating the fabrication of complex tissue structures.

Conductive Materials:

Conductive materials, such as graphene-infused filaments or metal nanoparticles, enable the 3D printing of electronic components and circuits. This allows for the creation of functional electronic devices, wearable technology, sensors, and antennas. The UAE’s focus on technological innovation makes conductive materials a valuable resource in the country’s 3D printing industry.

Conclusion:

The United Arab Emirates (UAE) embraces a wide range of materials in 3D printing applications. Thermoplastics, including PLA, ABS, and PETG, are commonly used for prototyping and consumer products. Polyamide (Nylon), photopolymer resins, polypropylene, and metal alloys find applications in various industries for functional parts and end-use components.

Carbon fiber-reinforced polymers, wood, and metal composites cater to specialized aesthetic and engineering requirements. Bioinks and biodegradable materials are utilized in biomedical applications, while silicone is preferred for flexible and soft structures. The diverse selection of materials in 3D printing enables the UAE to explore innovative designs, sustainable manufacturing, and customized solutions across industries.